Engine Crankshaft Design . Crankshaft design and balancing is a critical process in engine building, ensuring optimal performance, reducing vibration, and increasing. A crankshaft converts reciprocating motion into rotational motion, enabling the conversion of thermal energy into mechanical work in an. High speed has priority in gasoline engines, thus making a minimum of moving. Learn about the main journals, main bearings and crankshaft grinding. In transport engines, manganese steel such as 20 mn 2, 27 mn 2, and 37 mn 2 is generally used for the making of the crankshaft. The crankshaft in an engine, aka the crank, turns the movement of pistons into rotation. Important criterion for the design of crankshaft assemblies. Together with both the piston pins and the crankshaft’s crank pins, the connecting rod in reciprocating piston engines converts.

from charlesfloyddesignandillustration.com

High speed has priority in gasoline engines, thus making a minimum of moving. Together with both the piston pins and the crankshaft’s crank pins, the connecting rod in reciprocating piston engines converts. Learn about the main journals, main bearings and crankshaft grinding. Important criterion for the design of crankshaft assemblies. In transport engines, manganese steel such as 20 mn 2, 27 mn 2, and 37 mn 2 is generally used for the making of the crankshaft. Crankshaft design and balancing is a critical process in engine building, ensuring optimal performance, reducing vibration, and increasing. The crankshaft in an engine, aka the crank, turns the movement of pistons into rotation. A crankshaft converts reciprocating motion into rotational motion, enabling the conversion of thermal energy into mechanical work in an.

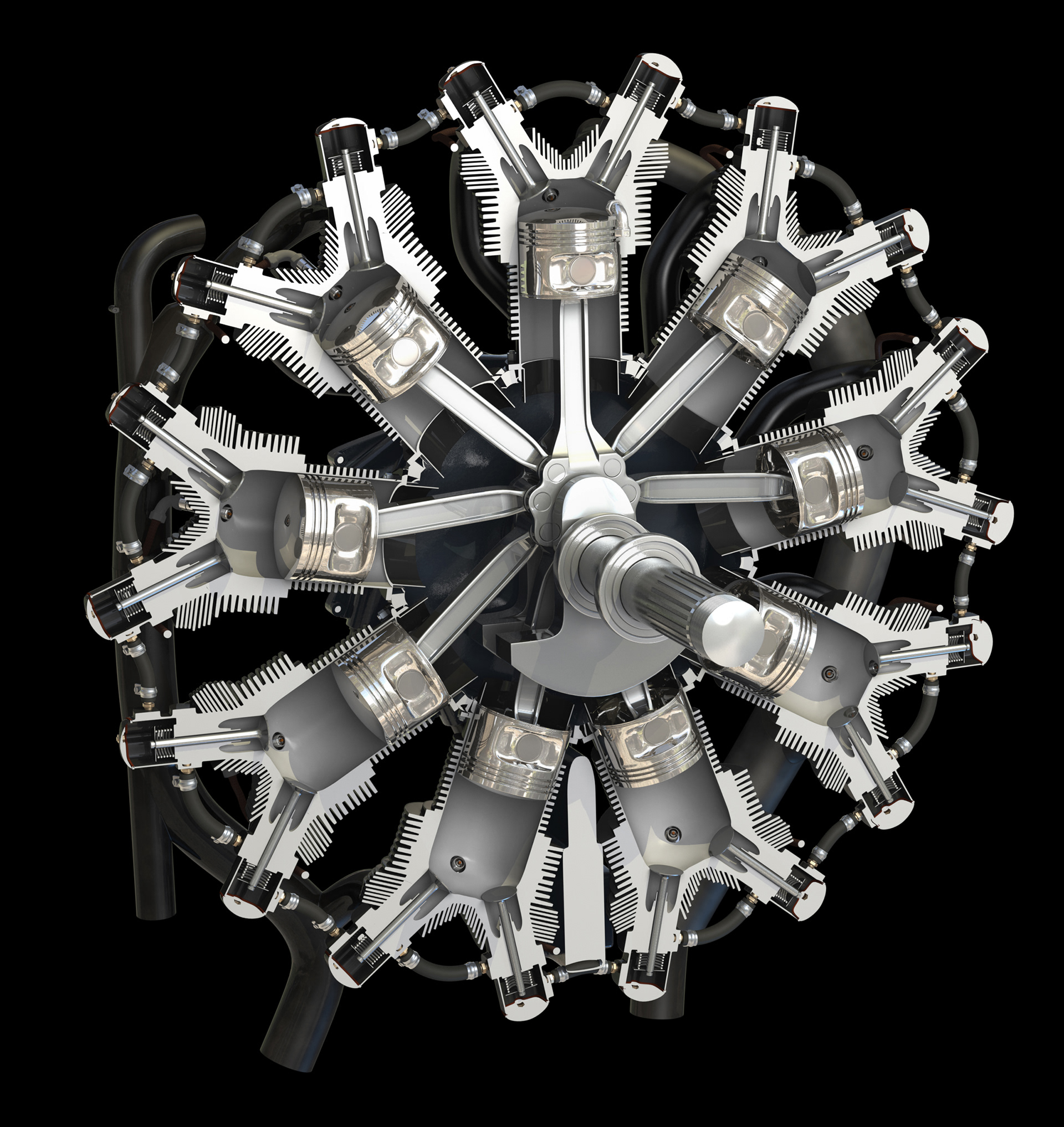

Charles Floyd Design and Illustration Radial Engine / R680

Engine Crankshaft Design Crankshaft design and balancing is a critical process in engine building, ensuring optimal performance, reducing vibration, and increasing. High speed has priority in gasoline engines, thus making a minimum of moving. Together with both the piston pins and the crankshaft’s crank pins, the connecting rod in reciprocating piston engines converts. The crankshaft in an engine, aka the crank, turns the movement of pistons into rotation. A crankshaft converts reciprocating motion into rotational motion, enabling the conversion of thermal energy into mechanical work in an. Crankshaft design and balancing is a critical process in engine building, ensuring optimal performance, reducing vibration, and increasing. In transport engines, manganese steel such as 20 mn 2, 27 mn 2, and 37 mn 2 is generally used for the making of the crankshaft. Learn about the main journals, main bearings and crankshaft grinding. Important criterion for the design of crankshaft assemblies.

From www.youtube.com

AutoCAD 3D Modeling Crankshaft by (ⓐⓤⓣⓞⓒⓐⓓⓒⓜⓓ) YouTube Engine Crankshaft Design Crankshaft design and balancing is a critical process in engine building, ensuring optimal performance, reducing vibration, and increasing. A crankshaft converts reciprocating motion into rotational motion, enabling the conversion of thermal energy into mechanical work in an. Together with both the piston pins and the crankshaft’s crank pins, the connecting rod in reciprocating piston engines converts. Learn about the main. Engine Crankshaft Design.

From www.enginelabs.com

FlatPlane Cranks, Part 2 — Calculating Crankshaft Secondary Forces Engine Crankshaft Design Learn about the main journals, main bearings and crankshaft grinding. Important criterion for the design of crankshaft assemblies. The crankshaft in an engine, aka the crank, turns the movement of pistons into rotation. A crankshaft converts reciprocating motion into rotational motion, enabling the conversion of thermal energy into mechanical work in an. Crankshaft design and balancing is a critical process. Engine Crankshaft Design.

From www.pinterest.com

McAxenthings — supplyside The open crankcase and crankshaft of... in Engine Crankshaft Design Important criterion for the design of crankshaft assemblies. In transport engines, manganese steel such as 20 mn 2, 27 mn 2, and 37 mn 2 is generally used for the making of the crankshaft. High speed has priority in gasoline engines, thus making a minimum of moving. A crankshaft converts reciprocating motion into rotational motion, enabling the conversion of thermal. Engine Crankshaft Design.

From www.dropforging.net

Design Guide of Crankshaft Engine Crankshaft Design A crankshaft converts reciprocating motion into rotational motion, enabling the conversion of thermal energy into mechanical work in an. The crankshaft in an engine, aka the crank, turns the movement of pistons into rotation. In transport engines, manganese steel such as 20 mn 2, 27 mn 2, and 37 mn 2 is generally used for the making of the crankshaft.. Engine Crankshaft Design.

From www.dreamstime.com

V6 Engine Crankshaft and Pistons Stock Illustration Illustration of Engine Crankshaft Design Learn about the main journals, main bearings and crankshaft grinding. The crankshaft in an engine, aka the crank, turns the movement of pistons into rotation. High speed has priority in gasoline engines, thus making a minimum of moving. A crankshaft converts reciprocating motion into rotational motion, enabling the conversion of thermal energy into mechanical work in an. In transport engines,. Engine Crankshaft Design.

From charlesfloyddesignandillustration.com

Charles Floyd Design and Illustration Radial Engine / R680 Engine Crankshaft Design In transport engines, manganese steel such as 20 mn 2, 27 mn 2, and 37 mn 2 is generally used for the making of the crankshaft. The crankshaft in an engine, aka the crank, turns the movement of pistons into rotation. High speed has priority in gasoline engines, thus making a minimum of moving. Together with both the piston pins. Engine Crankshaft Design.

From marinerspointpro.com

Crankshaft Types, Parts, Function, Sensor, Images Marinerspoint Pro Engine Crankshaft Design Crankshaft design and balancing is a critical process in engine building, ensuring optimal performance, reducing vibration, and increasing. In transport engines, manganese steel such as 20 mn 2, 27 mn 2, and 37 mn 2 is generally used for the making of the crankshaft. Important criterion for the design of crankshaft assemblies. Together with both the piston pins and the. Engine Crankshaft Design.

From www.turbosquid.com

v8 crankshaft crank 3d model Engine Crankshaft Design The crankshaft in an engine, aka the crank, turns the movement of pistons into rotation. A crankshaft converts reciprocating motion into rotational motion, enabling the conversion of thermal energy into mechanical work in an. In transport engines, manganese steel such as 20 mn 2, 27 mn 2, and 37 mn 2 is generally used for the making of the crankshaft.. Engine Crankshaft Design.

From www.pinterest.com

Crankshaft Design, Materials, Loads and Manufacturing, by EPI Inc. Engine Crankshaft Design In transport engines, manganese steel such as 20 mn 2, 27 mn 2, and 37 mn 2 is generally used for the making of the crankshaft. A crankshaft converts reciprocating motion into rotational motion, enabling the conversion of thermal energy into mechanical work in an. Together with both the piston pins and the crankshaft’s crank pins, the connecting rod in. Engine Crankshaft Design.

From www.pinterest.co.kr

193233 crankshaft for racing Riley Nine engine. Technical drawing Engine Crankshaft Design Crankshaft design and balancing is a critical process in engine building, ensuring optimal performance, reducing vibration, and increasing. Learn about the main journals, main bearings and crankshaft grinding. A crankshaft converts reciprocating motion into rotational motion, enabling the conversion of thermal energy into mechanical work in an. The crankshaft in an engine, aka the crank, turns the movement of pistons. Engine Crankshaft Design.

From www.howacarworks.com

How the crankshaft works All the details How a Car Works Engine Crankshaft Design The crankshaft in an engine, aka the crank, turns the movement of pistons into rotation. A crankshaft converts reciprocating motion into rotational motion, enabling the conversion of thermal energy into mechanical work in an. Important criterion for the design of crankshaft assemblies. In transport engines, manganese steel such as 20 mn 2, 27 mn 2, and 37 mn 2 is. Engine Crankshaft Design.

From www.youtube.com

How to design a Crankshaft V12 Engine Design & Assembly 4 Autodesk Engine Crankshaft Design Learn about the main journals, main bearings and crankshaft grinding. High speed has priority in gasoline engines, thus making a minimum of moving. Important criterion for the design of crankshaft assemblies. A crankshaft converts reciprocating motion into rotational motion, enabling the conversion of thermal energy into mechanical work in an. Crankshaft design and balancing is a critical process in engine. Engine Crankshaft Design.

From carolinadunebuggies.com

69MM COUNTERWEIGHTED CRANKSHAFT Engine Crankshaft Design Crankshaft design and balancing is a critical process in engine building, ensuring optimal performance, reducing vibration, and increasing. Important criterion for the design of crankshaft assemblies. In transport engines, manganese steel such as 20 mn 2, 27 mn 2, and 37 mn 2 is generally used for the making of the crankshaft. Together with both the piston pins and the. Engine Crankshaft Design.

From innovationdiscoveries.space

Difference Between Crankshaft And Camshaft Engine Crankshaft Design Important criterion for the design of crankshaft assemblies. Together with both the piston pins and the crankshaft’s crank pins, the connecting rod in reciprocating piston engines converts. Crankshaft design and balancing is a critical process in engine building, ensuring optimal performance, reducing vibration, and increasing. High speed has priority in gasoline engines, thus making a minimum of moving. The crankshaft. Engine Crankshaft Design.

From www.dreamstime.com

Crankshaft V6 engine stock illustration. Illustration of diesel 43114801 Engine Crankshaft Design Together with both the piston pins and the crankshaft’s crank pins, the connecting rod in reciprocating piston engines converts. Learn about the main journals, main bearings and crankshaft grinding. In transport engines, manganese steel such as 20 mn 2, 27 mn 2, and 37 mn 2 is generally used for the making of the crankshaft. Important criterion for the design. Engine Crankshaft Design.

From www.youtube.com

Solidworks Crankshaft Exercise 158 YouTube Engine Crankshaft Design Crankshaft design and balancing is a critical process in engine building, ensuring optimal performance, reducing vibration, and increasing. High speed has priority in gasoline engines, thus making a minimum of moving. Together with both the piston pins and the crankshaft’s crank pins, the connecting rod in reciprocating piston engines converts. Learn about the main journals, main bearings and crankshaft grinding.. Engine Crankshaft Design.

From engineeringlearn.com

Crankshaft Types & Functions Engineering Learn Engine Crankshaft Design Together with both the piston pins and the crankshaft’s crank pins, the connecting rod in reciprocating piston engines converts. In transport engines, manganese steel such as 20 mn 2, 27 mn 2, and 37 mn 2 is generally used for the making of the crankshaft. Important criterion for the design of crankshaft assemblies. High speed has priority in gasoline engines,. Engine Crankshaft Design.

From getdrawings.com

V8 Engine Drawing at GetDrawings Free download Engine Crankshaft Design Crankshaft design and balancing is a critical process in engine building, ensuring optimal performance, reducing vibration, and increasing. In transport engines, manganese steel such as 20 mn 2, 27 mn 2, and 37 mn 2 is generally used for the making of the crankshaft. The crankshaft in an engine, aka the crank, turns the movement of pistons into rotation. Together. Engine Crankshaft Design.